About PEDOT:PSS

PEDOT-PSS is an advanced, electrically conductive polymer. It belongs to very unique family of materials called intrinsically conducting polymers. These polymers conduct electricity although they are fully organic and do not contain any metals. Other familiar example includes polyaniline (PANI) which has found limited applications such as in special capacitors.

PEDOT:PSS is the best electrically conducting polymer available to date, and is by far the most convenient and reliable material to work with, as is stable to air and humidity, and can be processed by conventional means.

Additional properties of PEDOT-PSS are described below:

PEDOT-

PEDOT:PSS is the best electrically conducting polymer available to date, and is by far the most convenient and reliable material to work with, as is stable to air and humidity, and can be processed by conventional means.

Additional properties of PEDOT-

- Blue colored. however, thin films afford transparent and conducting coatings.

- Available as solution in water and can be conveniently processed by conventional means.

- Forms flexible electrically conductive films.

- Stable to air. Can be processed in ambient environment as well as high temperatures (~130C)

- Water based solutions are more environmentally friendly and are less restricted by regulations.

- PEDOT:PSS is not considered toxic material.

Structure and Chemistry of PEDOT:PSS

PEDOT:PSS is the common acronym for: Poly(3,4-

CAS# [150090-

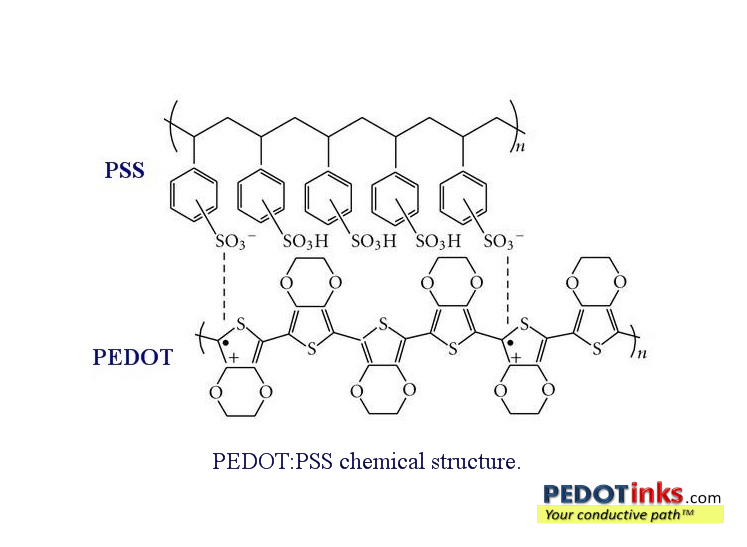

More specifically, it is a blend of two polymers: polymerized thiophene derivative (PEDOT) and polystyrenesulfonic acid (PSS).

PEDOT:PSS belongs to the polymeric group of polythiophenes. Polythiophene compounds also include organic semiconductors such as P3HT, as well as Lisicon® produced by Merck. These organic semiconductors find their application in (organic field effect transistors (OFETs) with the intention of producing flexible processors and switching pixels on and off.

PEDOT-PSS products are also offered by other companies under various brands such as Cl eviosTM (registered trademark of Heraeus) and OrgaconTM (registered trademark of Agfa).

Pristine PEDOT:PSS Vs. PEDOT:PSS formulations

Pristine, regular PEDOT:PSS is usually a 1.3~3% solution in water and does not contain other additives. It has very limited spreading and adhesion.

In order to achieve the full electrical conductivity of PEDOT:PSS it is necessary to add ~5% organic solvent such as DMSO. This is true for any pristine PEDOT:PSS from any manufacturer.

We carry pristine PEDOT:PSS (called simply PEDOT:PSS) in our products.

Formulated PEDOT:PSS products already contain all the additives required to allow them to be applied in specified application and furnish coatings with suitable conductivity, transparency and mechanical stability. Our formulated products are designed for coating glass and plastic substrates. No further preparations are required.

Applications of PEDOT:PSS

Main applications of PEDOT:PSS are in flexible and printed electronic devices, such as organic light emitting diodes (OLEDs), solar cells, EL-films, displays, OFETs etc. as electrode or as intermediate layer. It may also be used for EMI shielding.

PEDOT: PSS and its formulations may be applied by using inkjet printers, screen printers, slot-die coaters as well as other printing and coating tools, as well as a paintbrush.

We are capable of working together with prospective clients on specialized formulations for specific applications required by costumer.

© Pedotinks.com

Disclaimer: The information provided herein, including all further technical advice are for general guideline purposes only. This information is based on our present knowledge and experience and is believed to be correct and reliable. However, no warranty is expressed or implied regarding accuracy of the information. In view of the many factors that may affect processing and application, THE SELLER MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. The User assumes all risk and responsibility for, any use or handling of any material beyond our direct control. It is the sole responsibility of the Buyer to test the performance and suitability of the Material on his/her applications. We reserve the right to make any changes according to technological progress or further developments. Nothing contained herein is to be considered as permission, recommendation, nor as an inducement to practice any patented invention without permission of a patent owner.